Address: DeZhou,ShanDong,China | WhatsApp: +86-15098941090 | E-mail: support@aikegroupco.com

Fan coil unit is a common air conditioning equipment, mainly composed of fan coil unit body, controller, water pump, water pipeline, electrical control cabinet and other parts. The working principle of fan coil unit is to use water as the medium and use the heat carrying capacity of water to transfer cold and heat to achieve the purpose of indoor air temperature control.

The fan coil unit is mainly composed of a fan, a heat exchange coil and a casing. It can be divided into standard and high static pressure types according to the external static pressure of the fan coil unit, and can be divided into two rows and three rows according to the number of rows of heat exchange coils. The heat exchange coil generally uses copper tubes with aluminum fins. The outer diameter of the copper tube is 10-16mm, the fin thickness is about 0.15-0.2mm, and the spacing is 2.0-3.0mm. The fan generally uses a double-inlet forward-curved blade centrifugal fan. The motor uses a capacitive 4-pole single-phase motor, three-speed speed, and the casing and condensate tray are insulated.

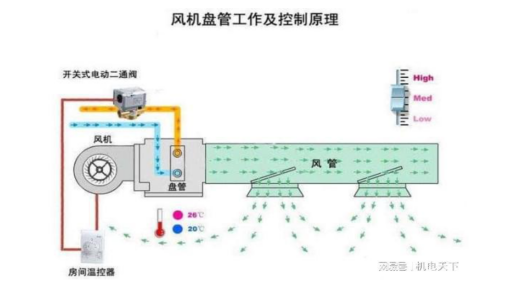

With the help of fan coil units, indoor air is continuously circulated, so that it is cooled or heated through the coil to maintain the required temperature and relative humidity of the room. The cold water or hot water used by the coil is supplied by the centralized cold source and heat source. At the same time, the fresh air processed by the fresh air air conditioning room is sent to each air-conditioned room through a special fresh air duct to meet the hygiene requirements of the air-conditioned room.

Compared with the centralized system, the fan coil air conditioning system has no large air duct, only water pipes and smaller fresh air ducts. It has the advantages of easy layout and installation, small building space occupation, and good individual adjustment. It is widely used in comfort air conditioning with low temperature and humidity accuracy requirements, large number of rooms, small rooms, and needs to be individually controlled.

Fan coil control mostly adopts local control scheme, which is divided into simple control and temperature control:

Simple control of fan coil: Use three-speed switch to directly manually control the three-speed conversion and start and stop of the fan.

Fan coil temperature control: Use thermostat to automatically control the opening and closing of electric two/three-way valve, three-speed conversion of fan, or directly control the three-speed conversion and start and stop of fan according to the comparison and calculation of set temperature and actual detection temperature, so as to achieve constant temperature by controlling the water flow or air volume of the system.

The working process of fan coil unit can be briefly described as follows: when the indoor temperature is higher than the set temperature, the controller will start the water pump, allowing water to flow through heat sources such as chillers or heat pumps to absorb cold and heat, and then the water will flow into the fan coil unit body, and transfer cold and heat to the indoor air through heat exchange plates or heat exchange tubes, lowering or raising the indoor temperature to the set temperature. When the indoor temperature reaches the set temperature, the controller will turn off the water pump and stop the fan coil.

The working and control principle of the fan coil is to achieve precise control of indoor temperature and air volume and improve comfort through the linkage of water and air circuits and intelligent adjustment of controllers and sensors.

Step 1: Clarify the type, specifications, air outlet position and other requirements of the selected unit

1. When selecting a fan coil unit refrigeration unit, the design preheating load is matched with the unit's sensible heat load. In most cases, the coil has sufficient latent heat capacity to meet the design requirements. If outdoor air is used, the load and calculation formula are adjusted accordingly: water temperature rise (℃) = air temperature rise (℃ db).

2. Heating: Usually, the unit selected for cooling has sufficient heating capacity, and the heat return is selected according to the same water flow rate, that is, the inlet water temperature is used to meet the required indoor heating load, indoor heating load , inlet air temperature (℃).

3. Cooling: Indoor preheating cooling load , indoor total heat cooling load , inlet air temperature (℃ db/℃ wb), inlet water temperature (℃), air volume.

Step 2 of fan coil unit selection: Determine parameters such as unit specifications, water volume, required water temperature and pressure drop.

1. Make it clear whether the fan motor bearing uses an oil-containing or oil-free shaft pump. If an oil-free shaft pump is used, it should be refueled regularly during use according to regulations.

2. Make it clear whether the water pipe of the selected unit is left or right (related to the pipeline layout, etc.).

3. In winter, hot water is used, and the water temperature generally does not exceed 60℃, which can reduce scaling and reduce the alternating effect of cold and hot, which weakens the expansion force of the expansion tube and affects heat transfer.

4. Pay attention to the insulation measures of the outlet water to avoid condensation during summer use and damage to indoor buildings.

5. Set an air release valve at the highest point of the unit coil.

The selection of fan coil units is relatively simple, and the price of fan coil units is not expensive, and maintenance is also relatively convenient, but choosing a suitable fan coil unit will undoubtedly add icing on the cake for the operation of the central air-conditioning system and make home life like a fish in water.