Address: DeZhou,ShanDong,China | WhatsApp: +86-15098941090 | E-mail: support@aikegroupco.com

From the literal meaning, we can know that there must be differences in the materials of galvanized steel water tanks and stainless steel water tanks, but most people don’t know much about the two, and they don’t know where the difference is. So, today I will introduce to you the differences between galvanized steel water tanks and stainless steel water tanks.The difference between galvanized steel water tanks and stainless steel water tanks1. Difference in materialsGalvanized steel water tank: It uses galvanized steel plate as raw material, immerses the thin steel plate in the molten zinc pool, and adheres a thin layer of zinc on the surface. It is mostly produced by continuous galvanizing process, and the whole roll of steel plate is continuously immersed in the galvanizing tank to form a galvanized plate. There are also a variety of materials to choose from, such as: electro-galvanized steel plate, alloyed galvanized steel plate, composite galvanized steel plate, and single-sided and double-sided galvanized steel plate.Stainless steel water tank: It is made of stainless steel plate. Common stainless steel plates include 201 stainless steel and 304 stainless steel. Among them, 304 stainless steel is a water tank plate that can store domestic water. It meets the standards for food use, has stable physical and chemical properties, and is resistant to most acidic substances and alkali solutions.2. Difference in service lifeBecause the galvanized layer of the galvanized steel plate water tank will be constantly worn during long-term use, and due to the erosion of moisture, acid and alkali in the environment, its service life is generally about 5-10 years. The service life of a stainless steel water tank can be more than 50 years because it is not affected by corrosion and rust.3. Difference in corrosion performanceThe material of the stainless steel water tank makes it have excellent corrosion resistance, is not easily corroded by acids, alkalis, salts and other substances, and can adapt to various harsh environmental conditions. Although the galvanized layer of the galvanized steel plate water tank can play a certain anti-corrosion role, its anti-corrosion performance may be affected in some harsh environments, such as high temperature, high humidity, acidic soil, etc.4. Difference in safety performanceStainless steel water tanks are made of food-grade stainless steel materials, which will not produce harmful substances. At the same time, they have good strength and sealing performance, and will not leak or deform. Galvanized steel water tanks may rust due to zinc wear during use, affecting their safety performance.5. Difference in priceDue to the high material and processing costs of stainless steel, the price of stainless steel water tanks is generally higher than that of galvanized steel water tanks.6. Difference in hygieneGalvanized steel water tank: After the zinc on the surface of the galvanized steel plate is oxidized, a dense zinc oxide film will be generated to isolate air and water vapor to prevent corrosion and rust, but it is not recommended to store domestic water. The corrosion resistance is general and does not meet the standards for food use.Stainless steel water tank: Made of food-grade 304 stainless steel, the dense oxide layer on the surface can resist the erosion of chlorine molecules in the air and water, has good corrosion resistance, and has no secondary pollution to the water quality. The water quality will not cause harm to the human body if it is stored for a long time, and the water quality can be kept clean for a long time, with a higher hygiene coefficient.7. Differences in installationGalvanized steel plate water tank: assembled with bolts, and sealing strips are used during assembly to reduce the occurrence of corrosion, rust, water seepage and other problems caused by improper welding at the weld.Stainless steel water tank: There are two installation methods: assembled and combined. It can be assembled by welding or bolts. There are various installation methods, fast installation speed, no restrictions on the site, high flexibility, and the volume of the water tank can be increased or decreased at will.8. Differences in application fieldsGalvanized steel plate water tank: Galvanized water tanks have the characteristics of high temperature resistance, impact resistance, corrosion resistance, high strength, and not easy to deform. They can store hot water in bathing centers and hot springs, as well as temporary water storage tanks for building water supply storage, construction, industry, fire protection, geological surveys, etc.Stainless steel water tank: 304 stainless steel plate can store drinking water, reduce the water supply pressure of urban pipe networks, and the problem of insufficient water supply in water plants. It is used more frequently in high-rise residential buildings, schools, etc. In industry, due to the corrosion resistance of stainless steel plates, it can be used to store chemical solutions.The above is the difference between galvanized steel water tank and stainless steel water tank. I hope it will be helpful to you!

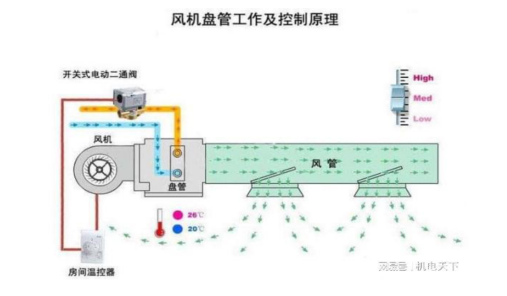

Fan coil unit is a common air conditioning equipment, mainly composed of fan coil unit body, controller, water pump, water pipeline, electrical control cabinet and other parts. The working principle of fan coil unit is to use water as the medium and use the heat carrying capacity of water to transfer cold and heat to achieve the purpose of indoor air temperature control.The fan coil unit is mainly composed of a fan, a heat exchange coil and a casing. It can be divided into standard and high static pressure types according to the external static pressure of the fan coil unit, and can be divided into two rows and three rows according to the number of rows of heat exchange coils. The heat exchange coil generally uses copper tubes with aluminum fins. The outer diameter of the copper tube is 10-16mm, the fin thickness is about 0.15-0.2mm, and the spacing is 2.0-3.0mm. The fan generally uses a double-inlet forward-curved blade centrifugal fan. The motor uses a capacitive 4-pole single-phase motor, three-speed speed, and the casing and condensate tray are insulated.With the help of fan coil units, indoor air is continuously circulated, so that it is cooled or heated through the coil to maintain the required temperature and relative humidity of the room. The cold water or hot water used by the coil is supplied by the centralized cold source and heat source. At the same time, the fresh air processed by the fresh air air conditioning room is sent to each air-conditioned room through a special fresh air duct to meet the hygiene requirements of the air-conditioned room.Compared with the centralized system, the fan coil air conditioning system has no large air duct, only water pipes and smaller fresh air ducts. It has the advantages of easy layout and installation, small building space occupation, and good individual adjustment. It is widely used in comfort air conditioning with low temperature and humidity accuracy requirements, large number of rooms, small rooms, and needs to be individually controlled.Fan coil control mostly adopts local control scheme, which is divided into simple control and temperature control:Simple control of fan coil: Use three-speed switch to directly manually control the three-speed conversion and start and stop of the fan.Fan coil temperature control: Use thermostat to automatically control the opening and closing of electric two/three-way valve, three-speed conversion of fan, or directly control the three-speed conversion and start and stop of fan according to the comparison and calculation of set temperature and actual detection temperature, so as to achieve constant temperature by controlling the water flow or air volume of the system.The working process of fan coil unit can be briefly described as follows: when the indoor temperature is higher than the set temperature, the controller will start the water pump, allowing water to flow through heat sources such as chillers or heat pumps to absorb cold and heat, and then the water will flow into the fan coil unit body, and transfer cold and heat to the indoor air through heat exchange plates or heat exchange tubes, lowering or raising the indoor temperature to the set temperature. When the indoor temperature reaches the set temperature, the controller will turn off the water pump and stop the fan coil.The working and control principle of the fan coil is to achieve precise control of indoor temperature and air volume and improve comfort through the linkage of water and air circuits and intelligent adjustment of controllers and sensors.Selection of fan coil units:Step 1: Clarify the type, specifications, air outlet position and other requirements of the selected unit1. When selecting a fan coil unit refrigeration unit, the design preheating load is matched with the unit's sensible heat load. In most cases, the coil has sufficient latent heat capacity to meet the design requirements. If outdoor air is used, the load and calculation formula are adjusted accordingly: water temperature rise (℃) = air temperature rise (℃ db).2. Heating: Usually, the unit selected for cooling has sufficient heating capacity, and the heat return is selected according to the same water flow rate, that is, the inlet water temperature is used to meet the required indoor heating load, indoor heating load , inlet air temperature (℃).3. Cooling: Indoor preheating cooling load , indoor total heat cooling load , inlet air temperature (℃db/℃wb), inlet water temperature (℃), air volume.Step 2 of fan coil unit selection: Determine parameters such as unit specifications, water volume, required water temperature and pressure drop.1. Make it clear whether the fan motor bearing uses an oil-containing or oil-free shaft pump. If an oil-free shaft pump is used, it should be refueled regularly during use according to regulations.2. Make it clear whether the water pipe of the selected unit is left or right (related to the pipeline layout, etc.).3. In winter, hot water is used, and the water temperature generally does not exceed 60℃, which can reduce scaling and reduce the alternating effect of cold and hot, which weakens the expansion force of the expansion tube and affects heat transfer.4. Pay attention to the insulation measures of the outlet water to avoid condensation during summer use and damage to indoor buildings.5. Set an air release valve at the highest point of the unit coil.The selection of fan coil units is relatively simple, and the price of fan coil units is not expensive, and maintenance is also relatively convenient, but choosing a suitable fan coil unit will undoubtedly add icing on the cake for the operation of the central air-conditioning system and make home life like a fish in water.

As part of the central air conditioning system, the fan coil unit is responsible for regulating the indoor temperature and humidity, but various faults may occur during use. This article introduces some common faults of the fan coil and their troubleshooting methods in detail to help users quickly solve the problem and ensure the normal operation of the air conditioning system.

1. Initial data evaluation and design: Analyzing the material and its temperature is crucial for establishing the correct storage conditions, which encompass temperature, pressure, and the limits of their application. Key considerations include the corrosive properties of the medium, qualitative attributes, vapor pressure, and accessibility, all of which serve as fundamental components in the design phase.2. Raw materials: When selecting materials for chemical storage tanks, the corrosive nature of the medium plays a crucial role. Depending on the operational pressure and temperature, options such as enamel-coated containers, glass-lined tanks, or steel pressure vessels lined with rubber, porcelain, or PTFE can be utilized to enhance corrosion resistance.3. Selection of GRP storage tank configuration: Various configurations, including horizontal and vertical orientations, as well as different head types, are available for specific applications. The selection process involves choosing from a national series of containers that align with the operational parameters, including working pressure, temperature, medium, and volume.4. Calculation of total volume: Establish a plan for the overall volume of material to be stored.5. Determination of unit quantity and dimensions: The total volume of stored materials is divided by the calculated volume of a glass fiber reinforced plastic tank to ascertain the required number of tanks. The appropriate tank volume is determined based on the tank type, characteristics of the stored material, site dimensions, processing capabilities, and other relevant factors. This comprehensive evaluation leads to the identification of the suitable tank volume, which, when combined with the total storage volume, informs the final decision on the number of tanks needed.

When selecting a supplier for GRP (Glass Reinforced Plastic) water tanks, it is essential to consider several key factors to ensure you make an informed choice that meets your water storage requirements. The right supplier plays a significant role in providing a dependable and long-lasting water storage solution. This guide will outline the critical aspects to evaluate when choosing a GRP water tank supplier. We will discuss elements such as product quality, certifications, customization options, and customer support, all of which are vital in making a well-informed decision. Join us as we delve into the four important considerations that will help you find the ideal GRP water tank supplier for your specific needs.Here Are Four Key Considerations for GRP Water Tank Suppliers:Quality and Longevity:The primary aspect to assess is the quality and longevity of the GRP water tanks provided by the supplier. Ensure that the tanks are constructed from premium materials capable of enduring various environmental conditions. A robust water tank from a reputable manufacturer will have an extended lifespan, minimizing the frequency of replacements. Look for certifications or industry standards that affirm the quality of the tanks.Supplier Credibility:Investigate the credibility of the supplier by examining customer reviews, testimonials, and any available online feedback. A dependable supplier will typically have a strong history of delivering high-quality products and exceptional customer service. Additionally, requesting references from the supplier can provide direct insights from previous clients. A reliable supplier is essential for ensuring a seamless and stress-free purchasing experience.Customization Options:Every water storage requirement is unique, and it’s essential to choose a supplier that offers customization options. Consider your specific needs such as size, shape, and additional features. A supplier willing to work with you to customize the water tank according to your requirements ensures that you get a solution tailored to your needs. This flexibility is crucial, especially when dealing with space constraints or specific installation requirements.Cost And Warranty:While cost is an important factor, it should not be the sole determinant. Compare the prices offered by different suppliers, but also consider the quality and features provided. Additionally, inquire about the warranty offered on the GRP water tanks. A reputable supplier will stand by their product and provide a reasonable warranty, giving you peace of mind regarding the longevity and performance of the tank.In conclusion, selecting a GRP water tank supplier involves careful consideration of quality, supplier reputation, customization options, and cost. By paying attention to these factors, you can make an informed decision that ensures you get a reliable and durable water storage solution that meets your specific needs. Always take the time to research and communicate with potential suppliers to guarantee the best outcome for your water storage requirements.Customization Options: Each water storage need is distinct, making it vital to select a supplier that provides customization options. Assess your particular requirements, including dimensions, design, and any additional features. A supplier that collaborates with you to tailor the water tank to your specifications guarantees a solution that fits your needs perfectly. This adaptability is especially important when facing spatial limitations or unique installation conditions.Cost and Warranty: Although price is a significant consideration, it should not be the only factor influencing your decision. Evaluate the costs from various suppliers while also taking into account the quality and features they offer. Furthermore, it is important to ask about the warranty associated with the GRP water tanks. A trustworthy supplier will support their product with a solid warranty, ensuring you have confidence in the tank's durability and performance.In summary, choosing a GRP water tank supplier requires thorough evaluation of quality, the supplier's reputation, customization capabilities, and pricing. By focusing on these elements, you can make a well-informed choice that provides a dependable and long-lasting water storage solution tailored to your specific requirements. Always invest time in researching and engaging with potential suppliers to ensure the best results for your water storage needs.