Address: DeZhou,ShanDong,China | WhatsApp: +86-15098941090 | E-mail: support@aikegroupco.com

We can offer with enamel coating panelled tanks as per customer requirement. These tanks can be with panels corresponding to metric size as well as imperial size. Also all these tanks carries CE certification too.

Email: support@aikegroupco.com

Whatsapp: +86-15098941090

The combined enamel steel water tank produced by our company adopts advanced technology and uses high-quality materials to ensure the clean water. Moreover, it is corrosionresistant and easy to clean. It has a longer service life than ordinary water tanks. It is easy to assemble, flexible , non-deformable, shock-resistant and impact-resistant. The product has been used well for a long time.

Our company has been mass-produced. Due to the generalization, guaranteed Enamel steel water tanks are used in a wide range of applications, not only for new construction,but also for the replacement of old building water tanks.

The Benefits of Enamel Water Tanks

Corrosion Resistance

A significant benefit of enamel water tanks lies in their remarkable resistance to corrosion. The vitreous enamel coating acts as a protective layer, safeguarding the underlying steel or cast iron from deterioration due to exposure to water and various corrosive substances. This resistance to corrosion contributes to the long-term durability and dependability of the water tank, minimizing the necessity for frequent repairs or replacements.

Hygienic Properties

Enamel water tanks are designed to be hygienic and suitable for the storage of potable water. The non-porous nature of the enamel surface inhibits the proliferation of bacteria, fungi, and other harmful microorganisms, thereby preserving the quality and purity of the water. This characteristic is especially crucial in scenarios where water is utilized for drinking, cooking, or other sanitary applications.

Easy Maintenance

Enameled water storage tanks require relatively minimal maintenance compared to other water storage solutions. The smooth, non-stick surface of the enamel coating facilitates easy cleaning and disinfection of the tank's interior, thereby reducing the risk of contamination and ensuring high water quality. Routine maintenance generally involves straightforward tasks such as periodic inspections for any damage or wear, along with occasional cleaning to eliminate sediment or buildup.

Temperature Resistance

Enameled water tanks demonstrate excellent resistance to temperature variations, enabling them to endure both hot and cold water applications without compromising their structural integrity or functionality. This quality makes them appropriate for a diverse array of water storage and distribution systems, including domestic hot water systems, industrial process water systems, and HVAC (heating, ventilation, and air conditioning) systems.

Aesthetic Appeal

Enameled water tanks are offered in a wide range of colors and finishes, enabling customization to harmonize with the surrounding environment or architectural style. The sleek, glossy surface of the enamel coating enhances the visual attractiveness of the water tank, making it a desirable addition to residential, commercial, and industrial spaces.

Environmental Sustainability

Enameled water tanks represent an environmentally responsible choice for water storage, as they are produced from recyclable materials and aid in resource conservation. Their extended lifespan diminishes the necessity for frequent replacements, thereby reducing waste and lessening the environmental impact associated with production and disposal.

Water Tank Structure

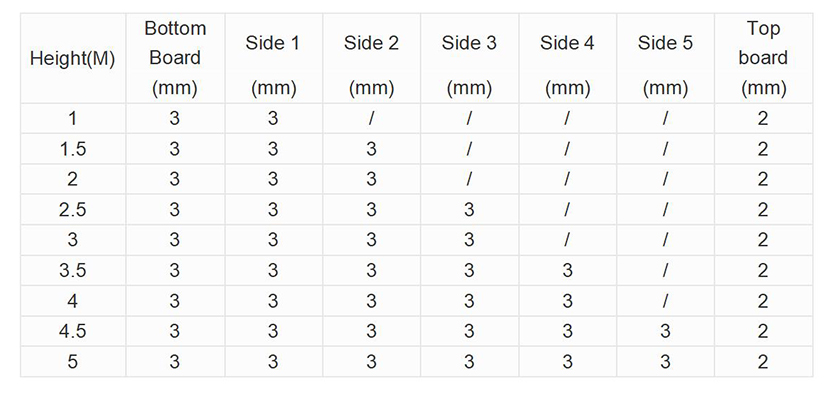

Enameled water tanks are generally constructed from enamel-coated panels that are assembled using bolts. The typical dimensions of these panels are 1 meter by 1 meter or 1 meter by 0.5 meters. By combining these panels, water tanks of various sizes and capacities can be designed to fulfill different customer needs.

The standard dimensions of the enamel panels facilitate easy customization of tank sizes and capacities based on customer requirements. Bolts are utilized to securely connect the enamel panels, ensuring the structural integrity and leak-proof characteristics of the water tank.

Thanks to their superior corrosion resistance and stain resistance, enamel water tanks are suitable for a variety of applications, including residential, commercial, and industrial sectors. They are frequently employed for storing cold water, hot water, industrial process water, and for fire protection systems, among other uses.

In conclusion, enamel water tanks are assembled by connecting enamel-coated panels with bolts, allowing for the customization of tank sizes and capacities to accommodate diverse needs across various applications.

Shipment

My shipment arrived early than with the expected date. Everything according to package was safely shipped to me with no defects. The supplier was excellent enough to satisfy the customer’s needs.

Selection instructions

1. The size of the water tank, the position of the pipe, and the diameter of the pipe should be provided when ordering.

2. The water tank can be supplied.

3. the use of storage temperature is preferably 4-65 °C When the storage temperature is higher than this value,it can be submitted at the time of ordering and will be solved separately.

4. No other weldments shall be welded inside or outside the water tank to prevent damage to the porcelain surface.

5. The load on the ground of the water tank shall be subject to the approval of the structural designer. 6. The water tank should be cleaned regularly to prevent debris from rushing into the tank when testing the water.

6. When the water tank tube position provided by the user is just at the seam of the board, the company needs to adjust it and the pipe diameter is unchanged (no further notice to the user.)

Installation and acceptance

1. Leave a maintenance passage of not less than 700 mm between the cabinet and the wall during installation .The top of the box and the bottom of the box are not less than 600mm.

2. The piers should be well prepared during the civil construction. The joints between the water tanks and the standard blocks at the bottom of the tank should be seated on the support