Address: DeZhou,ShanDong,China | WhatsApp: +86-18963078408 | E-mail: support@aikegroupco.com

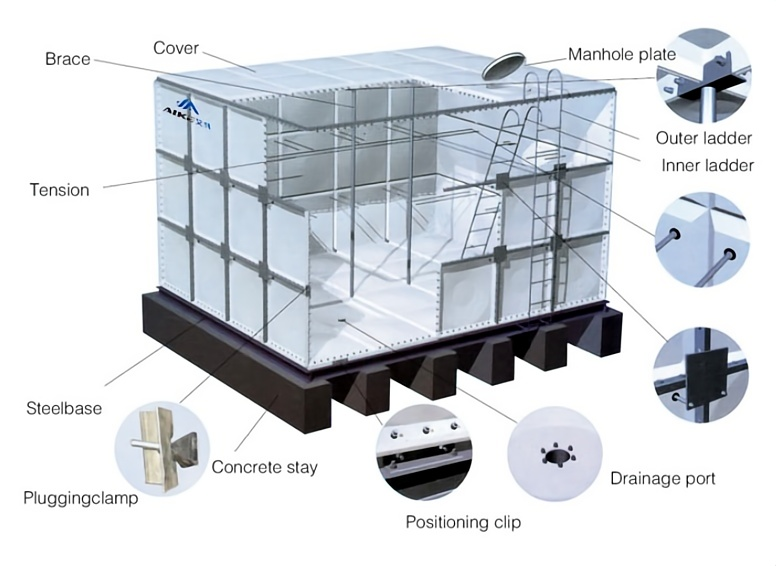

The manufacturing of the GRP/FRP/SMC/ water tanks utilizes food-grade resin and involves a process characterized by high temperature, high pressure, and mechanical pressing. This production method incorporates mechanical forming techniques that significantly improve resistance to earthquakes and impacts.

GRP Panel Performance And Specifications

The tank plate specifications are: 1000*1000mm; 1000*500mm; 500*500mm. The thickness is 4mm, 6mm,7mm,7.5mm, 9mm, 10mm, 12mm, 14mm. The 4mm thick ness plate is used for the water tank cover, Therefore, the water tank of the required capacity can be assembled at will.

Item | Performance index |

Tensile strength,MPa | ≥70 |

Bending strength,MPa | ≥100 |

Flexural modulus,Gpa | ≥7.0 |

Rarcnl hardness | ≥70 |

Water absorption rate,% | ≤1.0 |

Glass fiber content,% | ≥25 |

GRP Water Tank Advantage

● A New Type Of Water Tank Currently Used Internationally

● Increase The Seismic And Impact Strength And Improvethe Compressive Strength And Service Life.

● Selection Oflightweight, High-Strength, Corrosion-Resistant Nonmetallicpipes, Beautiful Appearance, Easy To Use, Maintain And Manage.

● With Ventilation, Lighting, Heat Dissipation, Anti-Skidexplosion-Proof And Other Properties

The GRP/FRP/SMC/ water tank is widely employed in numerous sectors, such as industrial and mining activities, businesses, educational institutions, residential complexes, hotels, restaurants, and various other facilities. It serves as an effective storage solution for potable water, fire suppression water, and other water types.

GRP/FRP/SMC/ Water Tank Video

Our company could also supply the Stainless Steel Water Tank, galvanized steel water tank, enameled water tanks, BDF undergroud water tank.

Welcome visit AIKE GROUP Youtube chanel to get more high quality water tanks video.

Shipment

My shipment arrived early than with the expected date. Everything according to package was safely shipped to me with no defects. The supplier was excellent enough to satisfy the customer’s needs.

Installation And Acceptance

1. When instaling. leave a maintenance pasage of not less than 700 mm between the box and

2. the wa.The top of the box and the botom ofthe box are not essthan 500mm

3. Duing the civil construction,the piers should be made first, and the joints between the water tanks and the bottom unit plates should be located on the butress.

4. After assembly, losethe outlet pipe and the drain pipe,open the inlet pipe,and checkthe wateruntilit is filed with water.The waterleakage for 24 hoursis acceptable.