Address: DeZhou,ShanDong,China | WhatsApp: +86-15098941090 | E-mail: support@aikegroupco.com

Hot Dip Galvanized Water Tank is a type of water storage container made from steel that has been subjected to a hot-dip galvanizing process and is designed in a rectangular shape.

Email: support@aikegroupco.com

Whatsapp: +86-15098941090

The hot dip galvanized water tank, commonly referred to as the HDG water tank, features a steel structure coated with a zinc finish. This zinc layer significantly enhances resistance to corrosion and degradation, providing protection for a minimum of ten years. It serves as a cost-effective solution for liquid storage, primarily utilized for oil and natural gas, firefighting water, industrial liquids, potable water, and wastewater management.

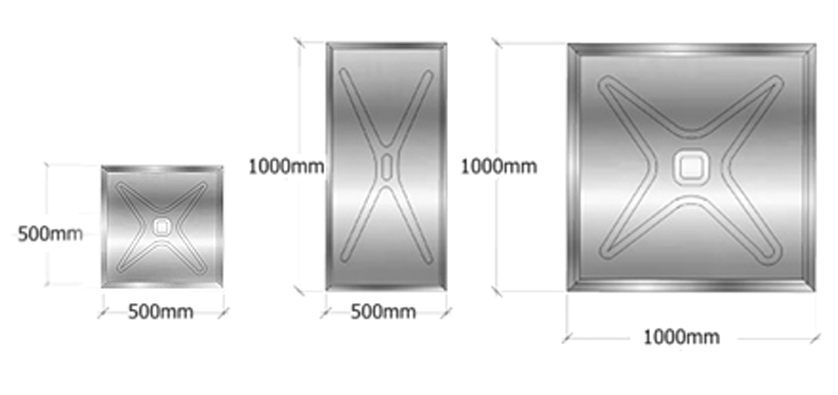

HDG water tank is available in a variety of panel sizes, including 1000 x 1000 mm, 1000 x 500 mm, and 500 x 500 mm.

The steel panel water tank series comprises three distinct types of water tanks:

The steel panel water tank series comprises three distinct types of water tanks:

1. Hot Dip Galvanized Steel Water Tank

This tank features carbon steel panels that are immersed in molten zinc, forming a Fe-Zn alloy. This process provides effective corrosion resistance against various liquids.

2. Enameled Steel Water Tank

The surface of this tank is coated with enameled steel, which protects the steel from rust. It consists of a single layer of black on the exterior and two layers of white on the interior, making it suitable for storing drinking water.

3. Gush-Paint Steel Water Tank

This tank utilizes electrostatic interaction to ensure that the powder adheres to the surface of the panel. The final coating effect is achieved through a high-temperature baking process.

Shipment

My shipment arrived early than with the expected date. Everything according to package was safely shipped to me with no defects. The supplier was excellent enough to satisfy the customer’s needs.

Installation and acceptance

1. When installing, leave a maintenance passage of not less than 700 mm between the box and the wall. The top of the box and the bottom of the box are not less than 500mm.

2. During the civil construction, the piers should be made first, and the joints between the water tanks and the bottom unit plates should be located on the buttress

3. After assembly, close the outlet pipe and the drain pipe, open the inlet pipe, and check the water until it is filled with water. The water leakage for 24 hours is acceptable.